STERN 3D

3D-PRINTING WITH MULTIJET FUSION TECHNOLOGY

How does 3D-Printing work at STERN 3D GmbH?

Configure online your 3D-Models and order directly

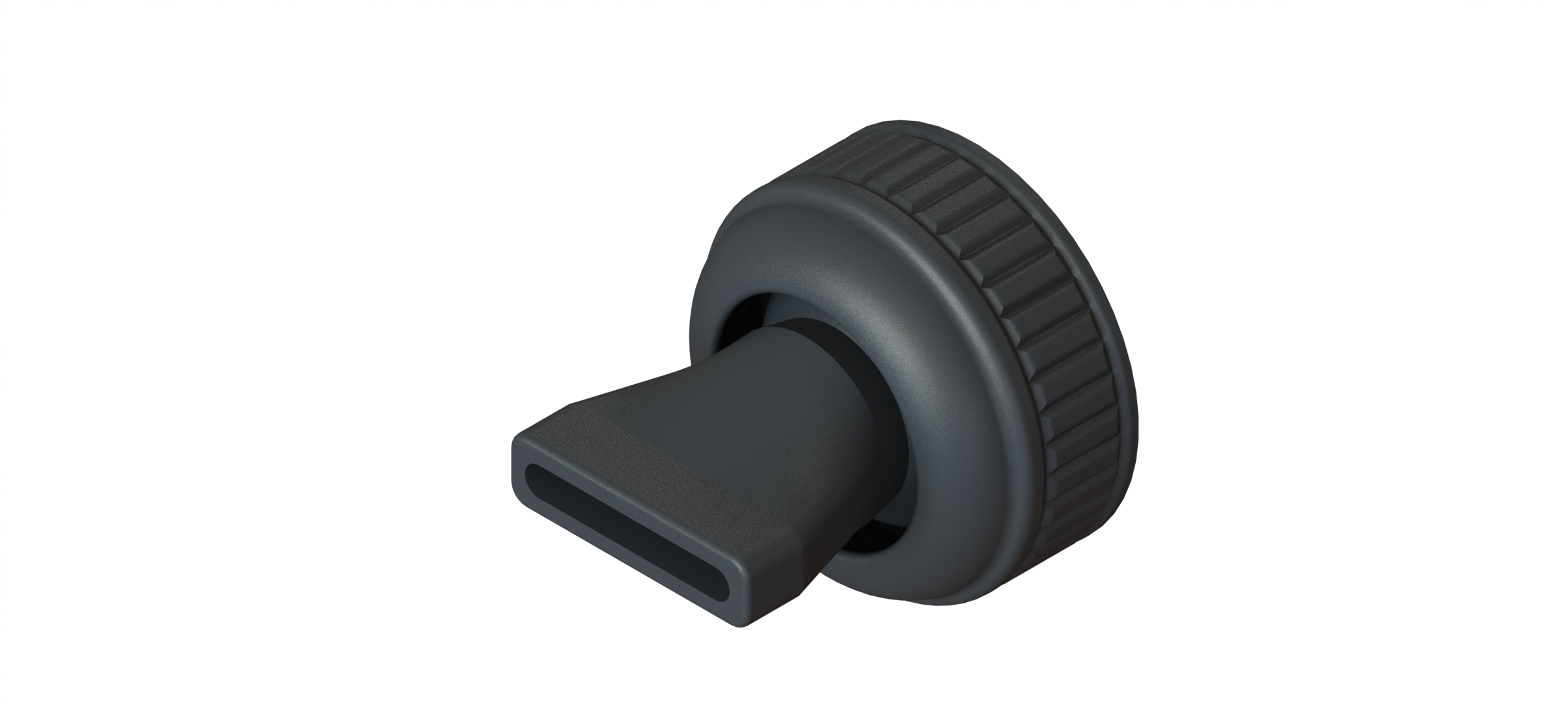

Kühlmittelverschlauchung

für Werkzeugmaschinen

EasCoS

Do you need more support?

Call us – We are happy to help you

Our Company

The name STERN has been associated with precision and reliability in industrial production for more than 60 years.

Die Stern 3D GmbH ist die konsequente Ergänzung unseres bisherigen Geschäftsfeldes für unsere Kunden.

Ausführliche Informationen über unseren Familienbetrieb finden Sie auf unserer Unternehmensseite.

Production

Whether you want a unique piece as an amateur designer, need prototypes or small series for OEMs or expect professional standard (industrial series production upto 40,000 parts) – we are the right address for you.

Best choice if you need…

- Workpieces

- Sample parts

- Prototypes and small series

- Demanding parts in series

- Serienfertiger, die anspruchsvolle Teile in Serie benötigen

Benefits

- Consulting and Design

- Keine Vorrichtung

- Keine Werkzeug- und Rüstkosten

- Short processing time

- Professional 3D-Printing

- Finishing on request

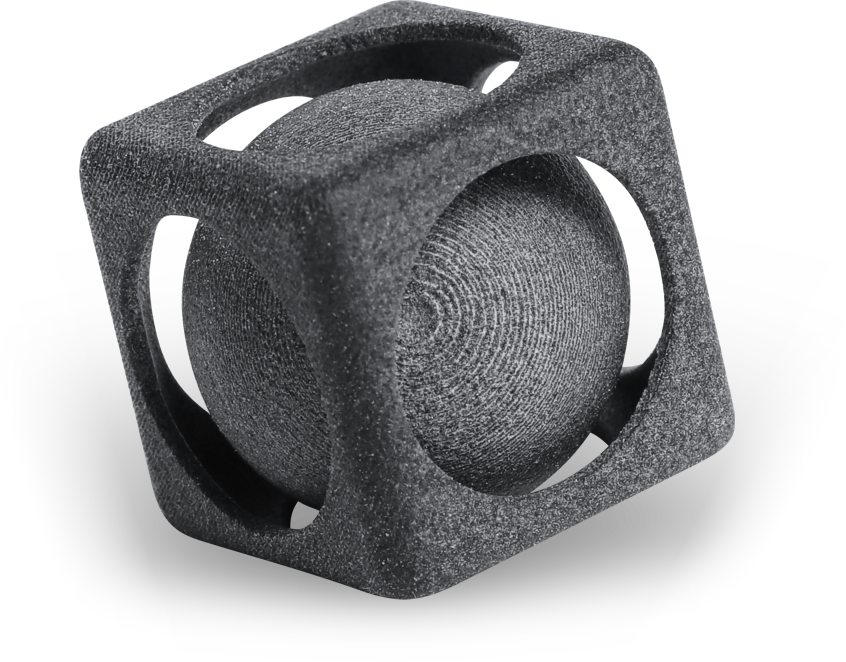

PERFECTION IN 3D

Sie haben die Idee – wir setzen Sie um!

For products that otherwise would not exist.

HP MULTIJET FUSION 4200

At the moment we use 6 pieces of Multijet Fusion 4200 from HP, actually the quickest available 3D-printer for quantity production (comparably at the speed of injection molding). In June 2018 we get additional 4 Multijet Fusion 4200.

More favourably produced, faster with you.

PROCESSING STATION

- Automatic mixing of material and systems-loading support the optimization of workflow and reduce working hours.

- With the included unpacking and material collection system (including laminar hood) there is no additional space for the removal of parts required.

- The printers HP Jet fusion 3D build unit is moved to the cooling immediately after completion of printing. This enables a continuous printing process and increase productivity.

- The HP Jet Fusion 3D Fast Cooling Module reduces the cooling-off period enables a shorter time per part and more parts that are ready same day.

WHY STERN 3D?

At STERN 3D GmbH you get everything from one source – from consulting and design to the finished product. As a HP-Reference Service Provider with one of the largest capacities of HP-3D printers of Europe we get maximum support by the manufacturer.