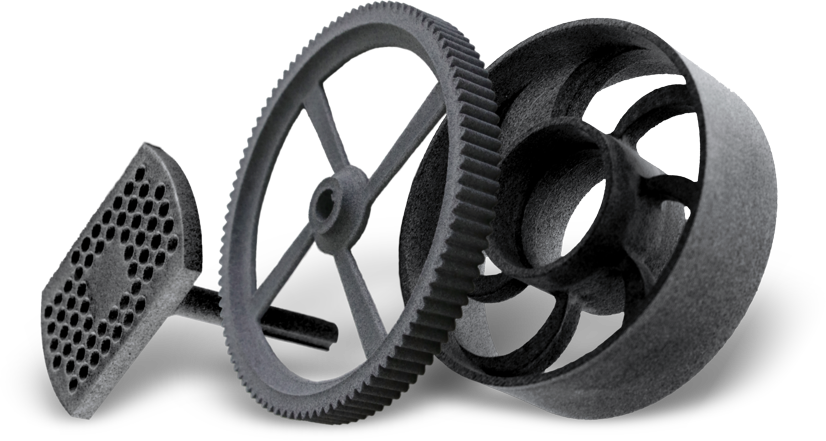

SERIAL PRODUCTION

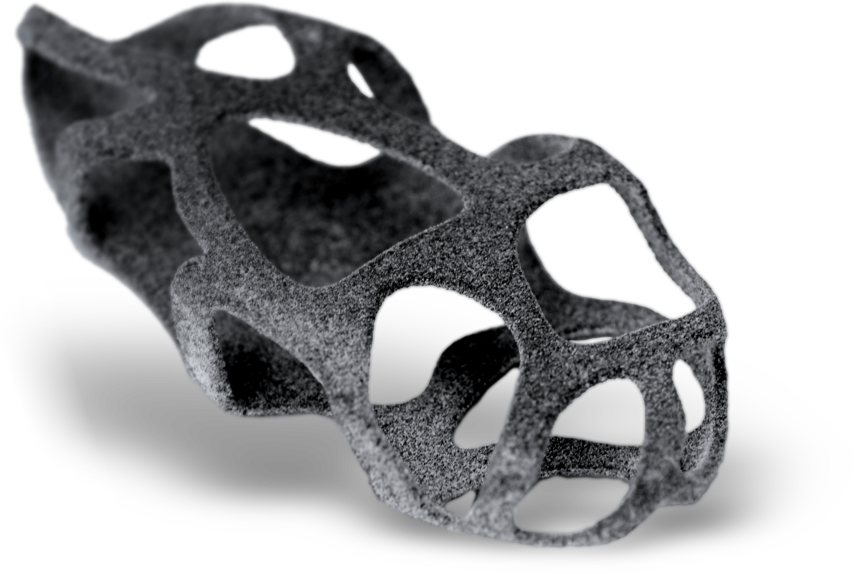

The capacity of 10 MJF printers from HP allows series production just in time. The corresponding number of processing stations and build units guarantee uninterrupted series production. The revolutionary technology from HP enables product designs that cannot be manufactured conventionally.

Design adjustments usually enable a reduction in costs, an improvement in (output) and an improvement in quality.

The STERN 3D GmbH is the perfect 3D-Partner for all industries.

We are looking forward to your challenge.

MATERIAL

We produce with „HP 3D high reusability PA 12“ for the production of stable, high-quality parts with high density at low per unit costs. Ideal for complex assemblies and housings. Parts manufactured with PA 12 are waterproof and resistant to oils, grease, aliphatic hydrocarbons and lyes.

The material was repeatedly certified with regard to its environmental impact, meets the USP classes I-VI and the US FDA guidelines for best skin compatibility.

The PA 11 and PA 12 materials with glass beads are also available in the near future.

On request we will send you a detailed product description of materials PDF format.

Finishing

On request, we perform a surface machining of your parts (beams, tumbling, dyeing or painting) in post processing.

Print Design

- For 3D printing, we need data in stl-format (CAD data), you can send us by E-Mail or on disk by mail.

- SIf you have no suitable data, we also like to create the necessary stl file for you. We use the CAD software SolidWorks.

- The same applies to those who have only one idea in mind: send us your sketch, we create the design together with you.The same applies to those who have only one idea in mind: send us your sketch, we create the design together with you.

- BPlease note:

The maximum printing size is 380 x 280 x 380 mm.

Das maximale Druckvolumen beträgt 380 x 280 x 380mm.

3D-PRINTFILES Upload

Do you have questions? Call us! We are happy to help you.

STATE OF THE ART TECHNOLOGY FOR

PERFECT RESULTS

Multi Jet fusion technology from HP requires no laser for 3D printing. The powder bed, in which the components are printed, is continuously heated by heating lamps during the printing process. The printheads spray a thermally conductive liquid onto the powder – thus, the component is built up layer by layer. At the outer edges, a transparent heat-resistant liquid is injected to ensure sharp contours and geometries. Lamps next to the printheads heat the injected liquid homogeneously so that the powder melts for a short time.